Busway General Information

To meet the need of the booming economic growth if the 1930s, busway systems were introduced to distribute power efficiently and reliably in high rise facilities. As the popularity of the busway grew in the US, later in the 1950s Japan and Europe began implementing these solutions.

It was EAE Electric who first started production and use of busway systems in Turkey in the 1970s.

Products

Busway Current Carrying Capacities

E-Line KX Busbar & Busbar Systems

Busbar Design | How did we develop the KX Busbar System?

Types of Busways According to the Current Intake Point

What is a bolt-on Busway?

Bolt-on Busway system: Busway systems that allow receiving of energy via current supply tap off boxes on joints of the Busway system.

Bolt-on: Used where current needs to be supplied from joints of the Busway system and direct supply is carried out.

What is a plug-in Busway?

Plug-in Busway system: Busway systems that allow receiving of energy via current supply tap off boxes on current supply (Plug-in point) windows on the housing of the Busway system.

Plug-in: Used where current is to be supplied from joints of the Busway systems and plug-in window. (Only straight modules)

Types of Busways According to Structure

What is Air Insulated Busway?

The most distinct specification of the air insulated Busway system is that there is a certain gap between the conductors and the Busway system functions in a closed metal body in an insulated environment provided with air.

The conductors (Aluminum or Copper) are not connected to each other as in the compact Busway system.

If the conductors used in the Busway system are in the range of 25A to 63A; conductors are placed in an insulated sheath (such as E-Line KY-S, E-Line DL/SL, E-Line KAM/KAP).

If the conductors used in the Busway system are 100A amperes and above; it is placed on post insulators at certain intervals (such as E-Line MK, E-Line KO-II). These systems are generally produced in a multiple tap-off distribution Busway structures.

What is Compact (Sandwich Type) Busway?

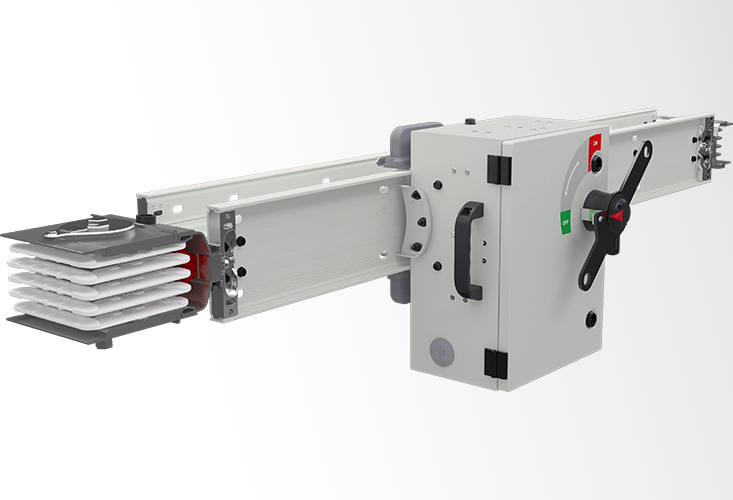

These are the compact (Sandwich Type) Busway systems, which are the latest stage in which robotic technology is used in its production.

The main specification of the compact Busway system is that after the conductors (Aluminum or Copper) are wrapped with insulation materials (primarily B class polyester film, which is coated with an epoxy or polypropylene insulating material and temperature resistant), they are placed in the metal body in the form of sandwiches without any air gap.

With the compact structure, the dimensions are minimized as much as possible according to the capacity of the energy carried. Since the distance between the conductors is minimized, the inductive reactance is reduced and accordingly the voltage drop is reduced.

Thanks to the housing that acts as cooling, heat transfer is supplied in the most ideal way. Sandwich Type Busway systems are produced from 400A and above.